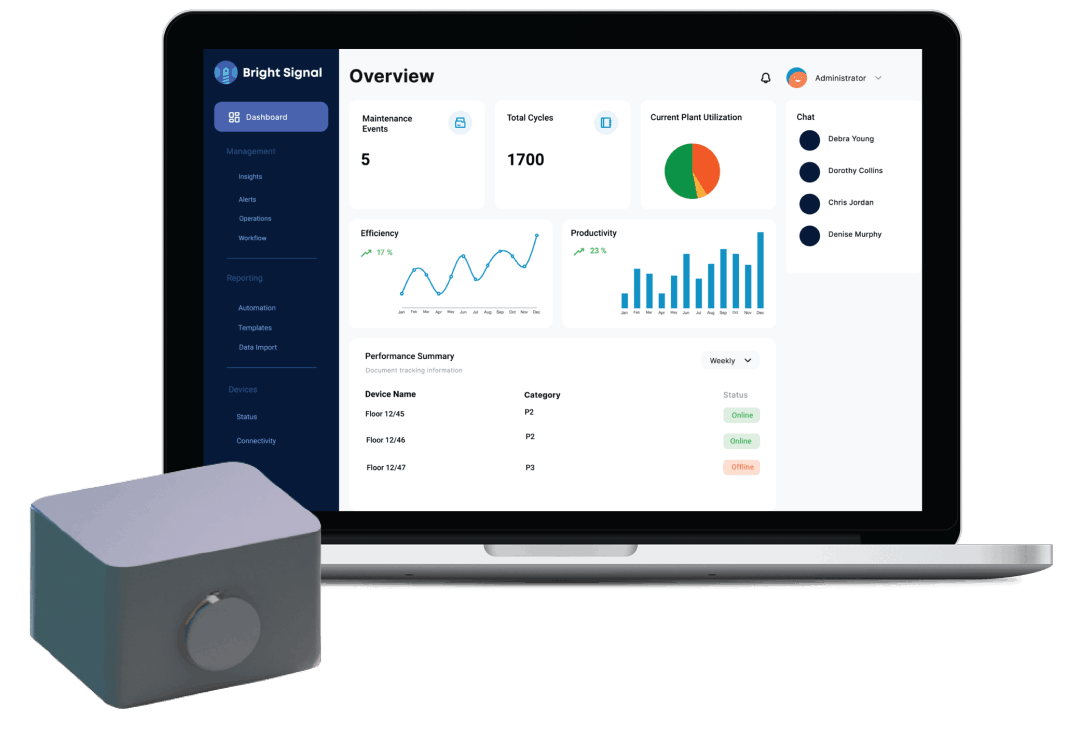

Bright Signal is AI-powered data management and predictive analytics platform tailored to plant managers and their team of maintenance engineers.

Many fear that AI technology strives to replace the human touch.

Bright Signal goes the other way around - it actually helps your team of engineers do their job more efficiently by

✓ Giving them ready-to-use insights that previously took a lot of time to analyze

✓ Supplying them with precise data in one place, rather than in many Excel sheets

✓ Helping them react on time to every change in your production lines

People do make errors, but machines aren’t perfect as well, and we know it.

Together, AI and your engineers make a powerful team that maximizes productivity.

As a data management and predictive analytics platform for manufacturing companies, combined with IoT, Bright Signal lets you collect and handle all of your data in one place.

✓ Predict machine downtime in advance

✓ Get actionable, data-backed insights from the machines

✓ Optimize your supply chain top-to-bottom

Eliminate failures with accurate and actionable insights – allowing your team to prevent individual assets from halting production in the first place.

Timely alerts lead to efficient repairs that

address the root cause of malfunctions

– increasing asset life cycles and reducing downtime for repairs.

Remote continuous monitoring protects technicians from recording on hard to reach or dangerous equipment while ensuring machines are working optimally for a safe work environment.

Smart wireless sensors connected to your machines monitor your assets 24/7.

Our advanced AI algorithm predicts machine downtime and alerts you on time.

Your maintenance team can react on time and keep your production smooth.

Thanks to the easy connectivity features, Bright Signal integrates seamlessly into all of your processes and actually reduces management efforts, because all of your data appears in one place.

No need to juggle between many different analytic tools anymore.

That’s a legitimate concern. Bright Signal uses your existing and effective data and gives downtime prediction based on that.

In other words, your experts have the last say. The only thing that can happen is that you spot opportunities to improve what you already have in place.

Implementing new tech isn’t easy, especially in companies that have established processes.

That’s why Bright Signal integrates with your existing tools, so you don’t have to modify processes.

We adapt it to your processes through business problem analysis beforehand, and continuous support along the way.

Yes, they do, and no, you don’t have to change anything.

Simply put, Bright Signal integrates every piece of data you have into one place and gives your experts a bird’s-eye overview of your orchard, thus making them more efficient in making decisions.

Bright Signal is a boost to their expertise, not a replacement for it.

That’s why we give you day-by-day support and training for a month, which in our experience with manufacturing companies, is more than enough to master Bright Signal.